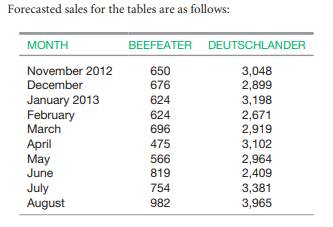

Castergourd Home Products makes two types of butcherblock tables: the Beefeater and the Deutschlander. The two tables are made in the same facility and require the same amount of labor and equipment. In addition, we know the following: Each table costs $300 to make, and each requires, on average, 3.2 hours of labor. Each employee works 160 hours per month, and there is no effective limit on the number of employees. The cost of hiring or laying off an employee is $300. The monthly holding cost for a table is $15. For planning purposes, Castergourd will begin and end with 20 employees and 0 tables in inventory.

a. (***) Develop a top-down level production plan for Castergourd for the 10-month planning period. Calculate the total production, hiring, layoff, and inventory costs for your plan. b. (***) Repeat part a, except in this case develop a chase production plan. c. (**) Suppose hiring and layoff costs increase dramatically. In general, will this make a level plan look better or worse than a chase plan? Explain.